Types of Screws for Kitchen Cabinet Installation

Choosing the right screws is crucial for a sturdy and long-lasting kitchen cabinet installation. The wrong screws can lead to stripped holes, wobbly cabinets, and ultimately, a frustrating and potentially costly repair. This section will detail the properties of various screw types to help you make informed decisions.

Screw Type Comparison

Selecting the appropriate screw depends heavily on the materials being joined. The following table compares common screw types used in kitchen cabinet installation, highlighting their strengths and weaknesses for different applications.

| Screw Type | Head Type | Material | Typical Uses |

|---|---|---|---|

| Wood Screws | Phillips, Flat, Square, Oval | Steel, Brass | Solid wood cabinets, joining wood components |

| Self-Tapping Screws | Phillips, Flat, Pan | Steel, Stainless Steel | Particleboard, plywood, metal-to-wood applications |

| Drywall Screws | Phillips, Flat | Steel | Generally unsuitable for kitchen cabinet installation; may be used for attaching very lightweight components to wall studs |

Advantages and Disadvantages of Screw Types

Wood screws, while requiring pre-drilled pilot holes, offer superior holding power in solid wood due to their sharp threads that bite into the material. They provide excellent strength and are less prone to stripping. However, they are not ideal for softer materials like particleboard, where they may split the wood.

Self-tapping screws are designed to cut their own threads, eliminating the need for pre-drilling in many cases. This makes them faster to install, particularly in softer materials like particleboard and plywood. However, they may not provide the same level of holding power as wood screws in solid wood, and improper use can lead to stripped holes. Stainless steel versions offer superior corrosion resistance in damp environments.

Drywall screws are specifically designed for drywall and lack the strength and holding power necessary for robust kitchen cabinet installation. Their use in this application is strongly discouraged, except for very minor, lightweight attachments to wall studs.

Screw Length and Application Recommendations

The following table provides guidelines for screw length selection based on cabinet material and thickness. Always err on the side of slightly longer screws to ensure adequate penetration and holding power. Shorter screws risk pulling through the material, leading to cabinet instability.

| Cabinet Material | Cabinet Thickness (mm) | Recommended Screw Length (mm) |

|---|---|---|

| Solid Wood | 18-25 | 30-40 |

| Plywood | 16-22 | 25-35 |

| Particleboard | 15-18 | 20-30 |

Note: These are general recommendations. Actual screw length may need adjustment depending on the specific application and construction details. Always pre-drill pilot holes in hard woods to prevent splitting. Using a countersinking bit will allow for a flush or slightly recessed screw head for a cleaner finish.

Factors to Consider When Choosing Screws: Best Screws For Installing Kitchen Cabinets

Selecting the right screws for kitchen cabinet installation is crucial for a secure and long-lasting result. Using the wrong screws can lead to cabinet instability, damage to the cabinets or walls, and ultimately, a frustrating and costly repair job. This section details a methodical approach to choosing the appropriate screws for your specific needs.

Cabinet Material and Weight

The material of your cabinets significantly impacts screw selection. Heavier cabinets made of solid wood require longer and thicker screws with greater holding power than lighter cabinets constructed from particleboard or MDF. For example, solid wood cabinets might need 2.5-inch screws, while lighter cabinets may only need 1.5-inch screws. Furthermore, the screw’s type should match the cabinet material; consider using wood screws for solid wood and self-tapping screws for particleboard or MDF to prevent splitting or stripping. Always check the manufacturer’s recommendations for specific screw types and sizes.

Wall Type and Construction, Best screws for installing kitchen cabinets

The type of wall you are attaching your cabinets to drastically influences screw selection. Attaching cabinets to wall studs provides superior stability compared to attaching them directly to drywall. When installing into studs, longer screws are generally necessary to penetrate deeply and securely fasten the cabinets. However, when attaching to drywall, you must use drywall anchors or specialized screws designed for drywall applications to prevent the screws from pulling out. The anchor’s holding capacity should be significantly higher than the weight of the cabinet to ensure a reliable installation. For instance, if installing a heavy cabinet onto drywall, consider using heavy-duty plastic anchors or even toggle bolts for increased support.

Screw Length and Pilot Holes: Preventing Damage and Ensuring Secure Installation

Using the correct screw length is paramount to prevent damage and ensure a secure installation. Too short a screw will not provide adequate support and could result in the cabinet pulling away from the wall. Too long a screw can penetrate through the cabinet backing or damage the wall behind it. Always measure twice and cut once. A good rule of thumb is to have at least 1 inch of screw penetrating the supporting member (stud or wall anchor).

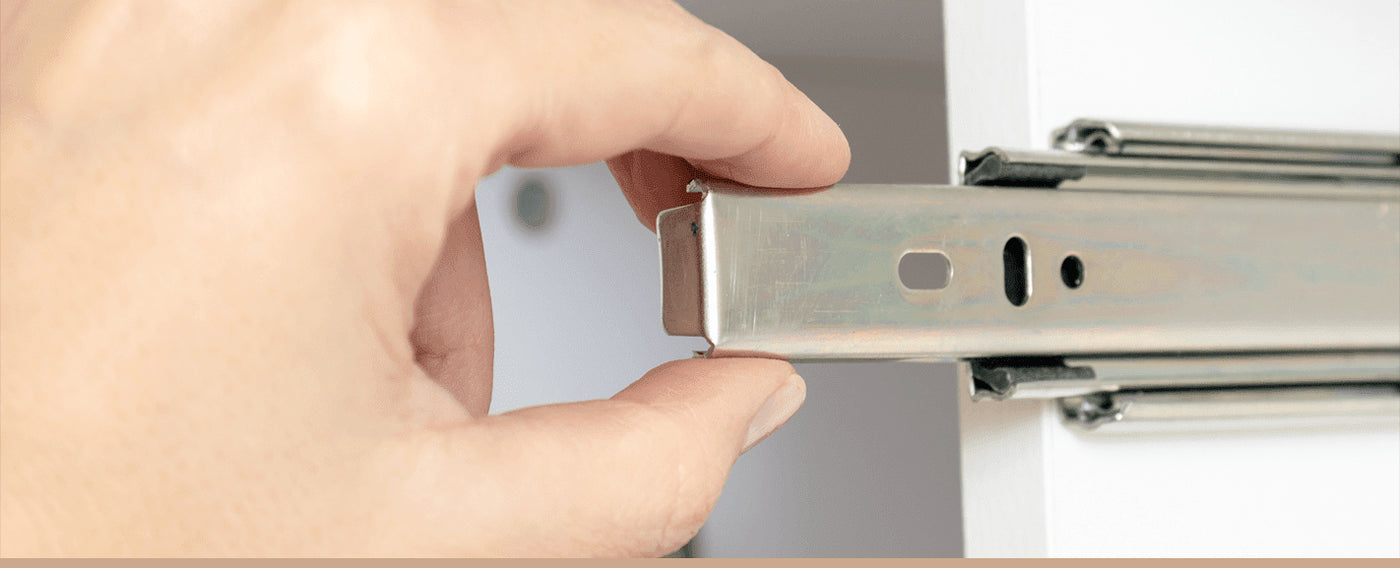

Pilot holes are essential to prevent wood from splitting, especially when working with hardwoods. A pilot hole should be slightly smaller than the screw’s shank diameter. A correctly drilled pilot hole will guide the screw straight, preventing it from wandering and potentially causing damage. The illustration below demonstrates the proper technique.

[Descriptive Illustration: The illustration should show a cabinet face, a wall stud, and a screw. A clearly marked pilot hole is shown drilled into the cabinet face, slightly smaller than the screw’s shaft. The screw is shown being driven into the pilot hole and the stud, with the correct depth clearly indicated.]

Potential Problems and Solutions

The importance of selecting the correct screws cannot be overstated. Using inappropriate screws can lead to several issues.

- Problem: Stripped screw holes. Solution: Use a pilot hole of the correct size, and avoid over-tightening. Consider using wood glue to reinforce the hole before reinstalling the screw.

- Problem: Cabinets pulling away from the wall. Solution: Use longer screws, ensure screws are properly seated into studs or use appropriate wall anchors, and consider adding additional support brackets.

- Problem: Damaged cabinet material. Solution: Use the correct size pilot hole, appropriate type of screw for the cabinet material, and avoid over-tightening. Use wood filler to repair any minor damage.

- Problem: Screws backing out over time. Solution: Use screws with good holding power, ensure screws are properly seated, and consider using a thread locker or additional support mechanisms.

Installation Techniques and Best Practices

Proper installation is crucial for ensuring the longevity and stability of your kitchen cabinets. Using the right screws and employing correct techniques prevents damage and ensures a professional-looking finish. This section details the procedures for installing cabinets using various screw types, emphasizing techniques to avoid common mistakes.

Installing Cabinets with Wood Screws

Wood screws are a staple in kitchen cabinet installation, offering excellent holding power in wood framing. For most applications, a #8 or #10 wood screw, 1 1/2″ to 2 1/2″ in length, is appropriate. The length will depend on the thickness of the cabinet and the wall stud.

Best screws for installing kitchen cabinets – Begin by pre-drilling pilot holes. This prevents splitting the wood and allows for easier screw insertion. The pilot hole diameter should be slightly smaller than the screw’s shank diameter. Use a countersink bit to create a recess for the screw head, preventing it from protruding and potentially scratching surfaces.

Position the cabinet against the wall, ensuring it’s level and plumb. Drive the screws through the cabinet’s mounting holes into the wall studs, using a screwdriver with a firm grip to avoid stripping the screw head. Avoid excessive force; the screw should go in smoothly. If resistance is met, check for obstructions or reposition the cabinet.

Imagine an image: A close-up shows a cabinet being secured to a wall stud. The screw is being driven in using a power screwdriver. The pilot hole is clearly visible, and the countersink is neatly finished, leaving the screw head flush with the cabinet surface. The cabinet is perfectly level and aligned.

Installing Cabinets with Drywall Screws

Drywall screws are useful for attaching cabinets to drywall, particularly in situations where studs aren’t readily accessible. However, they offer less holding power than wood screws. For this reason, they are often used in conjunction with cabinet anchors or toggles.

Pre-drilling pilot holes is essential with drywall screws to prevent the drywall from cracking. Use a smaller diameter pilot hole than with wood screws. The screw should be driven in straight to prevent it from pulling out of the drywall.

If using drywall anchors, follow the manufacturer’s instructions carefully. These anchors provide additional grip and support within the drywall cavity. For heavier cabinets, toggles offer superior holding power by expanding behind the drywall.

Imagine an image: This image displays a cabinet mounted to drywall using drywall screws and toggles. The toggles are clearly visible expanding behind the drywall. The screws are driven in straight, and the cabinet is securely fastened. The image highlights the difference in screw type and the added security provided by the toggles.

Preventing Stripped Screw Heads and Material Damage

Using the correct size screwdriver bit is paramount. A poorly fitting bit will strip the screw head. Always select a bit that precisely matches the screw head size. Apply even pressure when driving the screw; avoid using excessive force. If the screw resists, stop and reassess the situation. You might need to reposition the cabinet, pre-drill a larger pilot hole, or use a different type of screw. For delicate materials, consider using a lower torque setting on your power screwdriver.